Boiler is a machine that produces steam from the water resulting from combustion of fuels such as fibre, coal, black oil, gas, diesel. Boiler will conducting by several type of sensor. Commonly in industrial, they used PLC to move all operating of Boiler systems. This project mainly concerned on boiler control system (control panel) by using microcontroller PIC 16F877A.

Sunday, 11 November 2012

Boiler Control Panel

I have done to create a boiler panel which is this control panel will drive a Stepper motor. this panel also connected to temperature sensor and water pump

Tuesday, 23 October 2012

Stepper Motor

There are 2 type of Stepper Motor;

- Bipolar Stepper Motor

- Unipolar Stepper Motor

Unipolar Stepper Motors

The unipolar stepper motor has five or six wires

and four coils (actually two coils divided by center connections on each coil).

The center connections of the coils are tied together and used as the power

connection. They are called unipolar steppers because power always comes in on

this one pole.

Bipolar stepper motors

The bipolar stepper motor usually has four wires

coming out of it. Unlike unipolar steppers, bipolar steppers have no common

center connection. They have two independent sets of coils instead. You can

distinguish them from unipolar steppers by measuring the resistance between the

wires. You should find two pairs of wires with equal resistance. If you’ve got

the leads of your meter connected to two wires that are not connected (i.e. not

attached to the same coil), you should see infinite resistance (or no

continuity).

Like other motors, stepper motors require more

power than a microcontroller can give them, so you’ll need a separate power

supply for it. Ideally you’ll know the voltage from the manufacturer, but if

not, get a variable DC power supply, apply the minimum voltage (hopefully 3V or

so), apply voltage across two wires of a coil (e.g. 1 to 2 or 3 to 4) and

slowly raise the voltage until the motor is difficult to turn. It is possible

to damage a motor this way, so don’t go too far. Typical voltages for a stepper

might be 5V, 9V, 12V, 24V. Higher than 24V is less common for small steppers,

and frankly, above that level it’s best not to guess.

To control the stepper, apply voltage to each of

the coils in a specific sequence. The sequence would go like this:

|

Step

|

wire 1

|

wire 2

|

wire 3

|

wire 4

|

|

1

|

High

|

low

|

high

|

low

|

|

2

|

low

|

high

|

high

|

low

|

|

3

|

low

|

high

|

low

|

high

|

|

4

|

high

|

low

|

low

|

high

|

To control a unipolar stepper, you use a Darlington

Transistor Array. The stepping sequence is as shown above. Wires 5 and 6 are

wired to the supply voltage.

To control a bipolar stepper motor, you give the

coils current using to the same steps as for a unipolar stepper motor. However,

instead of using four coils, you use the both poles of the two coils, and

reverse the polarity of the current.

The easiest way to reverse the polarity in the

coils is to use a pair of H-bridges. The L293D dual H-bridge has two H-bridges

in the chip, so it will work nicely for this purpose.

Once you have the motor stepping in one direction,

stepping in the other direction is simply a matter of doing the steps in

reverse order.

Knowing the position is a matter of knowing how

many degrees per step, and counting the steps and multiplying by that many

degrees. So for examples, if you have a 1.8-degree stepper, and it’s turned 200

steps, then it’s turned 1.8 x 200 degrees, or 360 degrees, or one full

revolution.

Two-Wire Control

Thanks to Sebastian Gassner for ideas on how to do

this.

In every step of the sequence, two wires are always

set to opposite polarities. Because of this, it’s possible to control steppers

with only two wires instead of four, with a slightly more complex circuit. The

stepping sequence is the same as it is for the two middle wires of the sequence

above:

|

Step

|

wire 1

|

wire 2

|

|

1

|

low

|

high

|

|

2

|

high

|

high

|

|

3

|

high

|

low

|

|

4

|

low

|

low

|

The circuits for two-wire stepping are as follows:

Unipolar stepper two-wire circuit:

Biolar stepper two-wire circuit:

Programming the Microcontroller to Control a

Stepper

Because both unipolar and bipolar stepper motors

are controlled by the same stepping sequence, we can use the same

microcontroller code to control either one. In the code examples below, connect

either the Darlington transistor array (for unipolar steppers) or the dual

H-bridge (for bipolar steppers) to the pins of your microcontroller as

described in each example. There is a switch attached to the microcontroller as

well. When the switch is high, the motor turns one direction. When it’s low, it

turns the other direction.

The examples below use the 4-wire stepping

sequence. A two-wire control program is shown for the Wiring/Arduino Stepper

library only.

Wire pins 9-12 of the BX-24 to inputs 1-4 of the

Darlington transistor array, respectively. If you’re using the PicBasic Pro code,

it’s designed for a PIC 40-pin PIC such as the 16F877 or 18F452. Use pins

PORTD.0 through PORTD.3, respectively. If you’re using a smaller PIC, you can

swap ports, as long as you use the first four pins of the port.

Note that the wires read from left to right. Their

numbers don’t correspond with the bit positions. For example, PORTD.3 would be

wire 1, PORTD.2 would be wire 2, PORTD.1 would be wire 3, and PORTD.0 would be

wire 4. On the BX-24, pin 9 is wire 1, pin 10 is wire 2, and so forth.

ULN2803A

Relay circuit

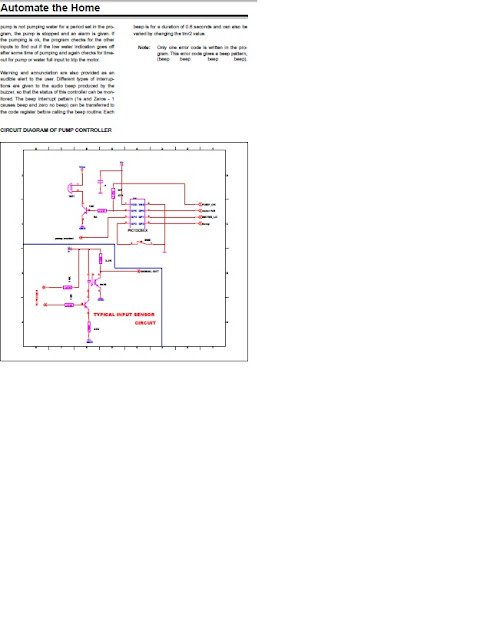

This is relay circuit, which is operate as switching circuit. This relay will operate when signal point of transistor which connected to PIC16877A and get a supply and also a signal to switch ON the relay, the relay will give a signal to operate a motor as we program it.

Above is a Relay circuit layout. This layout must be print at PCB paper, then iron it to PCB board before we etching by using acid liquid

Above is a Relay circuit layout. This layout must be print at PCB paper, then iron it to PCB board before we etching by using acid liquid

Friday, 12 October 2012

microcontroller circuit

POWER SUPPLY PIC CIRCUIT

Component for power supply:

1) Voltage regulator (REG 7805)

2) Diode (IN4007)

3) Switch (on/off)

4) Capasitor (100uF) & (100nF)

5) LED power

6) Resistor (470 ohm)

PIC CIRCUIT

I will post in a few day with diagram...

Component for power supply:

1) Voltage regulator (REG 7805)

2) Diode (IN4007)

3) Switch (on/off)

4) Capasitor (100uF) & (100nF)

5) LED power

6) Resistor (470 ohm)

PIC CIRCUIT

I will post in a few day with diagram...

Thursday, 11 October 2012

Monday, 1 October 2012

water level sensor circuit

prepared and construct the first circuit for WATER LEVEL SENSOR

This is a rough picture . According to this figure, I construct the circuit in PCB and I already done solder the PCB

This is a rough picture . According to this figure, I construct the circuit in PCB and I already done solder the PCB

Tuesday, 17 April 2012

week 13

- preparation progress report

- update blog

- hardware design

- order part of hardware

- research more about project

Thursday, 12 April 2012

week - 12

- flow chart project

- presentation day

- research more about project

- research component , equipment and installation

Friday, 6 April 2012

week - 11

— LITERATURE REVIEW

PLC (Programmable logic controller)

that is used for internal instruction storage and implementation of functions

such as sequencing, timing etc to control via digital I/O modules of various

types of machine processes. For several

of industry they used PLC to move Boiler operation . According En.Tarmizi as a technician in PPUKM, Boiler that

used in hospital are not suitable using PLC to move the operation of boiler.

-present preparation

-go research at HUKM

Thursday, 29 March 2012

Tuesday, 27 March 2012

Tuesday, 20 March 2012

Monday, 12 March 2012

week - 8. The main device in this project - PIC 16F877A

PIC 16F877A is the brain of the system and control all the function of the components to work properly. The program design with MPLAB to make sure it running smoothly. The display on the LCD can be monitored by engineer to ensure nothing incident and failure happen with the system or the device during operation. LCD will display the temperature and the pressure of the water inside the boiler tank.

Monday, 27 February 2012

week - 7 Objective project

Objective of this project is to introduce the microcontroller for industrial application. This project, aimed at diversifying the use of PIC, particularly in the boiler control. therefore, the application of PLC to be replaced, and also can reduce installation cost and easy for engineer to monitor the operation of Boiler.

Wednesday, 22 February 2012

week - 6 data sheet of water detector sensor

This is a Data sheet of water detector sensor, where it is will use at hardware part of this project

Friday, 17 February 2012

week - 5 introduction my project

- — Many microcontroller designs typically mix multiple interfacing methods. In a very simplistic form, a micro controller system can be viewed as a system that reads from (monitor) inputs, performs processing and writes to (control).

- —Our aim is to create a product based on PIC microcontroller. So we have come out with an idea to create a Boiler system by using PIC 16F877A.

- Boiler will operate when PIC controlling the system, so, it most easier for technician to conduct the operation of Boiler.

Tuesday, 14 February 2012

Friday, 10 February 2012

Thursday, 9 February 2012

week 4

- week 1 - get a supervisor

- week 2 - get a project title

- week 3 - research about the project,discussion with supervisor

- week 4 - create the project blog

Wednesday, 8 February 2012

Subscribe to:

Comments (Atom)